+86-159 9860 6917

info@geofantex.com

geofantex@gmail.com

+86-400-8266163-44899

What is Geosynthetics Clay Liner (GCL) – Geofantex

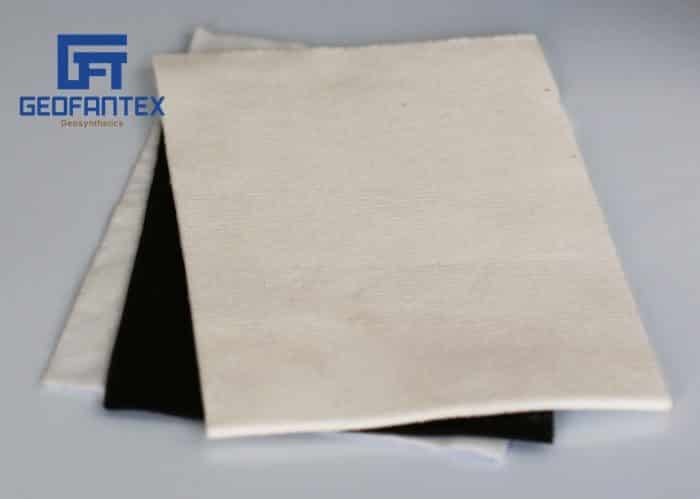

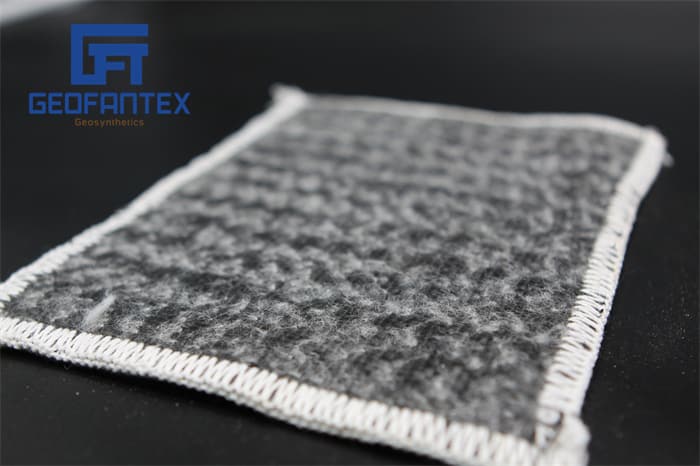

Geosynthetics Clay Liner (GCL), bentonite geosynthetics clay liner (GCL) is a new type of geosynthetic material. It is made of graded natural sodium-based bentonite particles and corresponding admixtures as raw materials. After the acupuncture process and equipment, the bentonite particles are fixed between the nonwoven geotextile fabric and the plastic woven geotextile to make a blanket waterproof membrane. Bentonite Geosynthetics Clay Liner not only has all the characteristics of geotechnical materials but also has excellent waterproof (permeability) performance.

Геосинтетический глиняный лайнер (GCL)

| SEPARATION | REINFORCEMENT | FILTRATION | DRAINAGE | WATERPROOF | PREVENTION | POLLUTION PREVENTION | PROTECTION | CONSOLIDATE | |

| GEOTEXTILE | √ | √ | √ | √ | √ | √ | |||

| GEOMEMBRANE | √ | √ | √ | ||||||

| GEOGRID | √ | √ | |||||||

| GEONET | √ | ||||||||

| GEOTUBE | √ | ||||||||

| GEOCELL | √ | √ | |||||||

| GCL | √ | √ | |||||||

| GEOCOMPOSITE | √ | √ | √ | √ | √ | √ | √ |

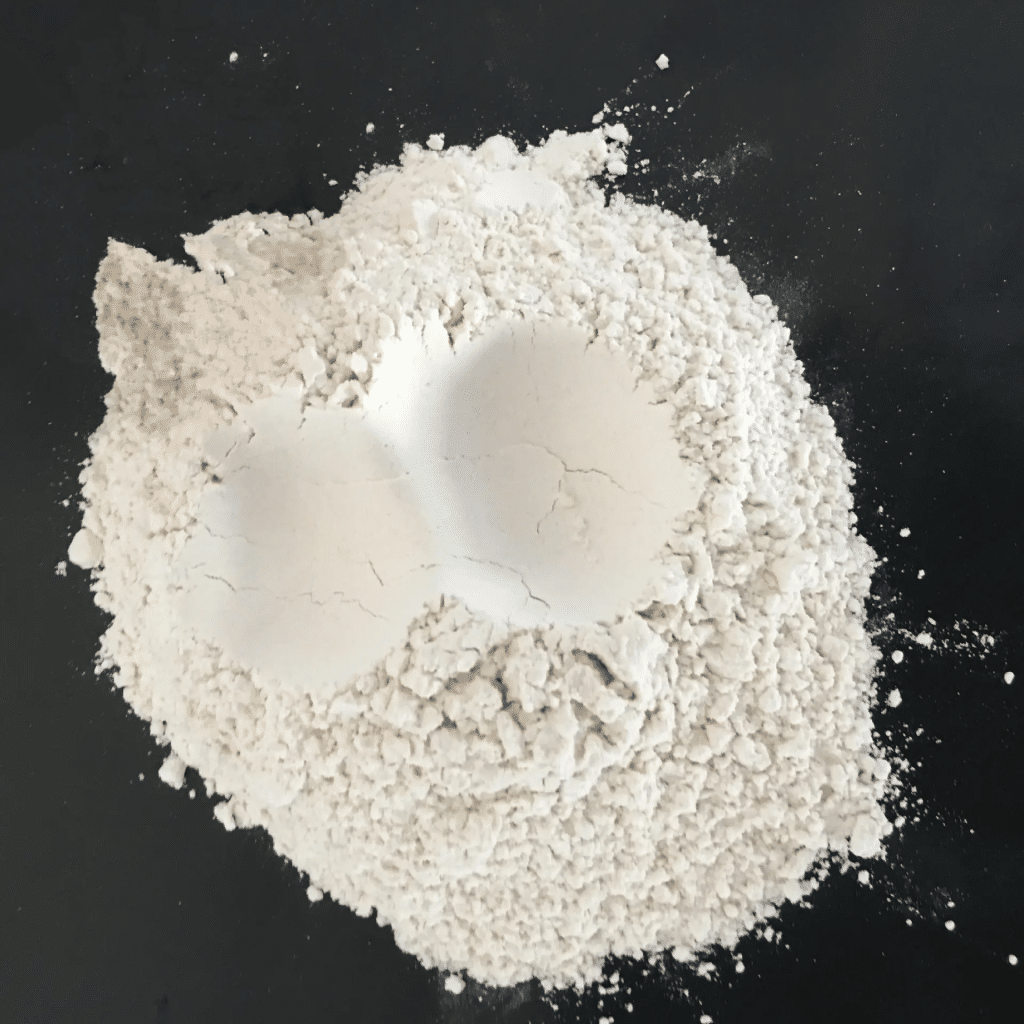

Principle of Bentonite

The mineralogy name of bentonite is montmorillonite, and natural bentonite is mainly divided into two categories: sodium base and calcium base according to chemical composition. Bentonite has the property of swelling when it encounters water. Generally, when calcium-based bentonite swells, its expansion is only about 3 times its own volume, while sodium-based bentonite absorbs water five times its own weight when it meets water, and its volume expands to 15-17 times its original volume. Above, the sodium-based bentonite is locked between two layers of geosynthetics to protect and strengthen the GCL, so that the GCL has a certain overall shear strength.

Geosynthetics Clay Liner Features

Density

Sodium-based bentonite forms a high-density diaphragm under hydraulic pressure. When the thickness is about 3mm, its water permeability is below &×10ˉ11m/sec, which is equivalent to 100 times the compactness of clay with a thickness of 30cm, and has strong self-water retention performance. .

Has permanent waterproof performance

Because sodium bentonite is a natural inorganic material, even after a long time or changes in the surrounding environment, it will not age or corrode, so the waterproof performance is durable.

Simple construction and short construction period

Compared with other waterproof materials, the construction is relatively simple and does not require heating and pasting. Simply connect and secure with bentonite powder and nails, washers, etc. No special inspection is required after construction, and it is easy to repair if waterproof defects are found. GCL has the shortest construction period among existing waterproof materials.

Not affected by temperature

It is also not brittle in cold climates.

Integration

Integration of waterproof materials and objects: When sodium-based bentonite meets water, it has an expansion capacity of 20-28 times. Even if the concrete structure vibrates and settles, the bentonite in GCL can also repair cracks on the concrete surface within 2mm.

Green

Bentonite is a natural inorganic material, harmless and non-toxic to the human body, has no special impact on the environment, and has good environmental performance.

How To Install Geosynthetics Clay Liner

- The Geosynthetics Clay Liner material has a large weight, so it should be transported and laid with a shovel machine and a waterproof blanket lifting tool.

- The connection of Geosynthetics Clay Liner material adopts the method of lap joint.

- When the Geosynthetics Clay Liner is laid on a slope greater than 10%, the number of overlaps along the length of the slope should be minimized, and the bentonite pad on the slope must exceed the foot line of the slope by more than 1500mm.

- Any equipment used for laying Geosynthetics Clay Liner cannot drive on the already laid geosynthetics. When installing the Geosynthetics Clay Liner, the outdoor air temperature should not be lower than 0°C or higher than 40°C.

- All exposed edges of the Geosynthetics Clay Liner must be immediately pressed with sandbags or other heavy objects to prevent the Geosynthetics Clay Liner from being blown by the wind or pulled out of the surrounding anchorage ditch. The Geosynthetics Clay Liner cannot be unfolded in windy weather to prevent it from being blown up by the wind.

- The laying method of the Geosynthetics Clay Liner must ensure that the Geosynthetics Clay Liner is in direct contact with the foundation below to eliminate wrinkles. Any folds, folds or arches may cause the same situation with other geotechnical materials in the soil layer. In order to avoid folds, folds and arches, we will relay or cut the Geosynthetics Clay Liner according to the requirements of the technical instructions. and fixes to eliminate these problems.

- The equipment of Geosynthetics Clay Liner must be approved by the supervision engineer before use, and the use of unprotected razors or “quick knives” is not allowed. The construction equipment that may damage the bentonite blanket cannot directly act on the bentonite blanket. The feasible laying method is to push the bulldozer backwards and spread the bentonite blanket at the front end of the bulldozer before hoisting. If the soil machine has left a car mark on the foundation soil, it should be restored to its original state before the laying work continues.

- When laying the bentonite blanket, try to reduce the dragging of the bentonite blanket on the foundation to avoid damage to the contact surface between the bentonite blanket and the ground. If necessary, a temporary geotextile can be placed on the ground to reduce the damage caused by friction during the laying of the bentonite blanket.

- The laying and lapping of bentonite blankets should be parallel to the slope direction

Get the latest price?

We’ll respond as soon as possible(within 12 hours)